Our History

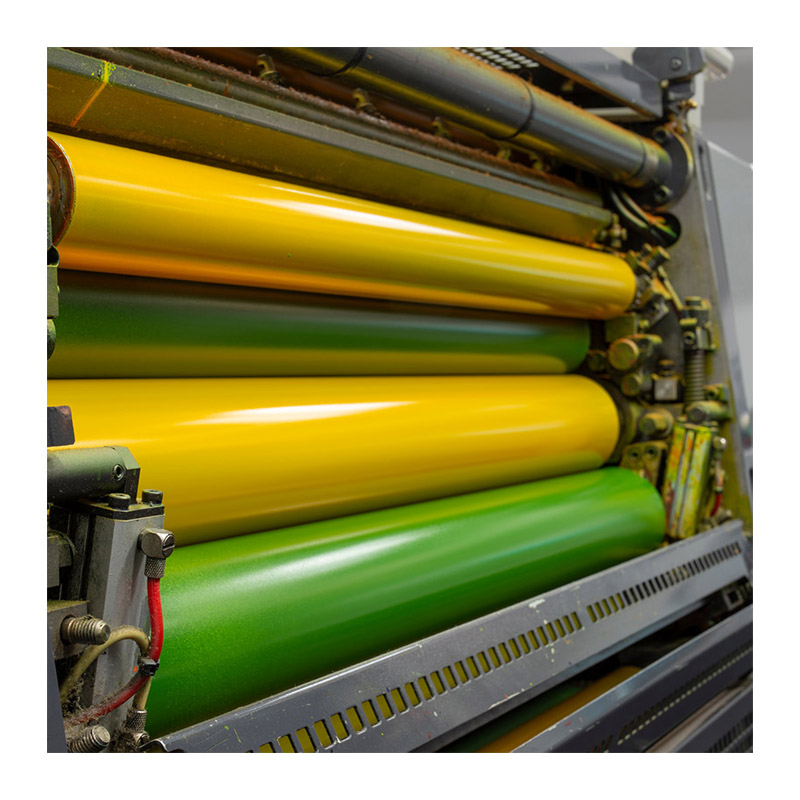

What we excel in is recognizing the technical trends and changes in the printing industry market and turning them into innovations. Already with the previous corporate composition, since the 1980s, we have explored and made ours, the idea of offset printing without the usage of dampening water, becoming on this way the broadest experts in Italy and in Europe.

PRINTING PRODUCTS

INKS

INKS

VARNISHES

VARNISHES

OTHER PRODUCTS

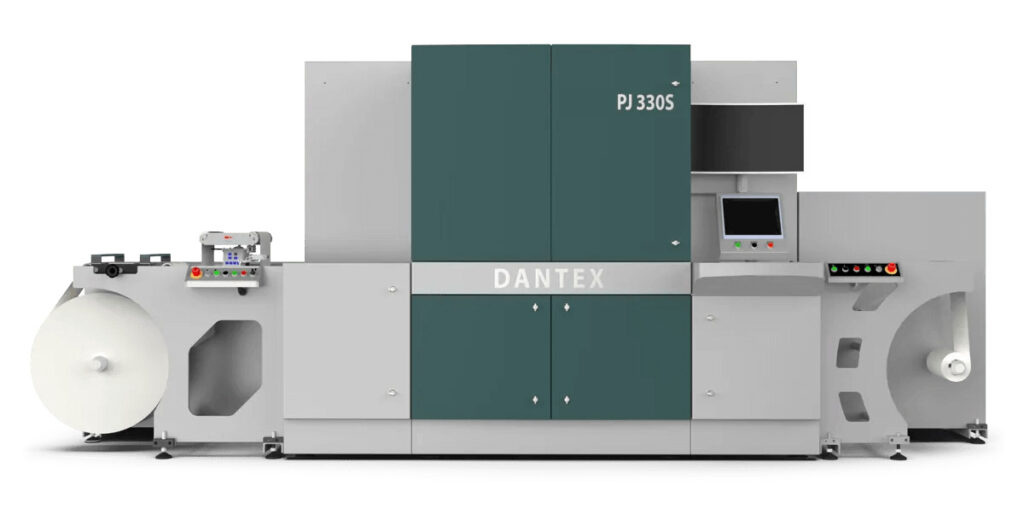

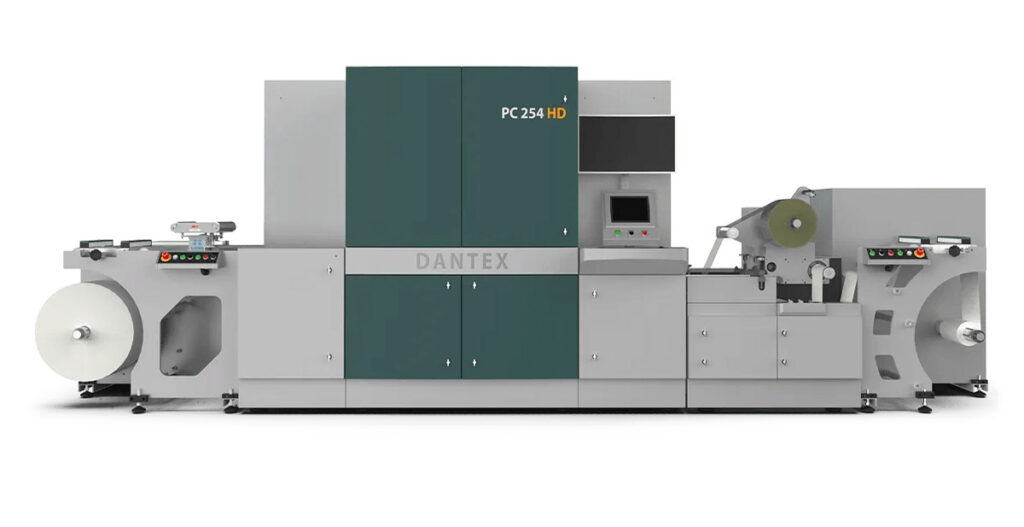

Official Dantex distributors

Dantex is at the service of the label and packaging industry for 50 years and has always been in the technical innovation to meet the specific needs of the market. Dantex is a key supplier for the industry supported by the excellence of its product portfolio competence to meet the changing needs and technologies of the label and packaging market.

The T&K Services

The T&K Services

The Lastest News From The Printing Industry

Printing service at UV LED of UV Ray

There are several companies in the Label world that, since the beginning of the year, have contacted UV Ray S.r.l. and T&K because interested at this new service which allows to optimize the printing process with LED technology systems.

How is the service structured?

UV Ray calculates which UV systems with lamps or LED are necessary to optimize the printing process in terms of energy saving, evaluating which drying systems are more suitable for the UV printing of flexo labels with narrow band.

T&K defines a model also linked with the inks and varnishes, counting on a wide selection as well as a representative of different producers.

The process explained in detail by Carmelo Roberto and Stefano Maiano during this interview at MetaPrintArt.

More info at this link

T&K TOKA reinforces its own presence at global level

While in Asia “UV 161” is already synonimous of “UV ink”, T&K TOKA aims to reinforce its own assistance at a global level: in the last 4 years it has doubled-up the sales in North America and Europe, but the margin of growth is still wide and the company is constantly searching for international partnerships

Optimization of offset and flexo UV/UV LED printing process for labels

Do you have any questions?

To view all the questions click on the following link

1. Try to reduce the quantity of ink on the rollers through the UCR configuration during the preprinting step. Replace the ink with a higher coloring strenght one.

2. Try to reduce the quantity of dampening solution until the plate takes strength (“dry”). Check the adjustments of the rollers in the machine. Check the quantity and dilution of the dampening.

3. Reduce the temperature down to the value recommended by the machine manufacturer.

4. Replace with an ink that has the specific features for high speed.

1. Make sure the mix level of the dampening solution and the conductivity are in line with the suggested parameters.

2. Rinse properly all the plates after cleaning them.

2. Rinse properly all the plates after cleaning them.

4. Wash the plate completely; prepare a new plate if necessary.

5. Rimove the arabic gum with warm water. Make sure the thickness is going to be reduced in the future, both in the manual application and the automatic one (developer).

1. Adjust the pliers correctly.

2. Adjust the balance water/ink trying to reduce the quantity of water down to the low point. Use a paper quality that doesn’t fan out.

3. Fix the plate.

4. Retire the rubber based on the recommended setting; check the coating or replace everything if necessary.

WHO WE ARE

CONTACT US

Legal seat: Via Canonica 1,

20154 Milano

Tel.: +39 (02) 37920620

Fax: +39 (02) 39304121

info@tandk.it